Tool maintenance begins as soon as you get a hand tool. To increase the longevity of your hand tools and help them last a lifetime use these tool maintenance tips that grandpa used. If you do these things you can pass your tools on to the next generation.

They sure don’t make tools like they used to. Have you noticed that tools from Grandpa’s era seem to have a much longer lifespan than the tools we get at the hardware store now? In fact, you may even have a few of grandpa’s tools in your garage. Those tools just lasted longer. Is the metal weaker now? Are the tool handles less robust? Or did Grandpa know something about tool maintenance that we don’t?

Grandpa bought quality to start with

Grandpa didn’t buy the cheapest tool on the rack. He knew that a quality tool was an investment, not an expense. So grandpa looked at the tool he was purchasing, checked the keen edge, the weight and strength of the steel, and the quality of the handle before he made a purchase. Money wasn’t as plentiful in grandpa’s day and he wanted to make sure this tool purchase wouldn’t be necessary again.

Once he got that tool home, Grandpa did a few simple tasks to ensure that those tools maintained their sharp blades and smooth handles for a long time.

Grandpa preserved the tool’s handle

Most tools have ash, hickory, or maple handles. They are strong but generally unfinished. In fact, the unfinished handle is a mark of a quality wooden handle. Some manufacturers put a varnish on the handle to disguise inferior wood stock.

Grandpa took fine-grit sandpaper or a fine sanding block and brushed that handle in the direction of the grain to remove any splinters that may have roughed up the handle in transit. A smooth handle is easier on the hands.

Then grandpa took a cotton rag and a container of boiled linseed oil and rubbed that handle from top to bottom letting the linseed oil soak in for 30 minutes, before rubbing off the excess. Boiled linseed oil dries quickly on the wood and forms a thin polymer film that allows the wood to breathe while preventing the wood from drying out and cracking. It also preserves the wood from moisture damage and rot. Every wooden handle needs annual applications of boiled linseed oil to preserve it from moisture and rot and give it long life.

Grandpa knew that rags soaked in linseed oil needed to be dried on the line before being put away. Boiled linseed oil-soaked rags can heat up and spontaneously combust if they aren’t dried thoroughly. Remember that time the neighbour’s garage burnt down? That memory reminded grandpa to always dry his rags, after use.

Don’t ever take a linseed or turpentine soaked rag and toss it in a bucket and put it in the garage. That’s a disaster waiting to happen.

Grandpa rubbed down the leather tool covers

Leather axe head covers, leather bags, leather boots, saddles, and gear can dry out and stiffen over time. Leather left in an unheated garage or shed is susceptible to cracking if it isn’t preserved and maintained. A little leather balm or leather polish rubbed into the smooth side of the leather will preserve and protect your leather tools and covers from damage from humidity and rot.

You can make your own leather balm from the recipe in my book, The Beeswax Workshop, or you can buy a commercial product like Otter Wax Leather Salve, a secret mixture of beeswax, carnauba wax, and shea butter, with sweet orange essential oil and other undisclosed ingredients. Otter Wax is an American product made with natural ingredients.

Using a soft chamois rub a small amount of Leather Salve into the smooth side of the leather using circular motions. Wait for 30 minutes for the oil to be absorbed by the leather and then wipe away the excess salve. Buff the leather with a soft cloth until it is shiny and dry.

For dirty leather use saddle soap to clean the leather, before applying the Leather Salve. Saddle soap is used on dry or just barely damp leather. Thick suds are made on the surface of the saddle soap with a brush, and only the suds is brushed into the leather to loosen dried in dirt and lift grease. The leather is buffed and allowed to dry before the Leather salve or leather conditioner is rubbed into the leather. Saddle soap is used on both the smooth surface and the rough surface of the leather, to clean it.

Grandpa kept his tools sharp and rust free

Tool maintenance begins with cleaning and then sharpening hand tools, before using them and before storing them. Tools left out in the elements tend to dull and rust on the metal parts. Grandpa countered the tendency for the blade to dull by sharpening the blades of axes, hoes, chisels, and knives before using and before putting them away for a season. Many tools don’t come from the store ready for action. Many hand tools, like garden hoes, must be sharpened even before the first use. Check the blades of your garden tools and wood working tools to ensure they are sharp, before putting them away in proper storage.

If your blade is grimy or caked in dirt don’t wash it with water. Instead use an oily cloth or WD-40 to clean the grime off before you begin to sharpen the tool. Any sand or soil on the tool can easily destroy the edge, even as you are trying to sharpen it so take the time to clean it before sharpening.

To sharpen a tool you must begin by deciding how much of a sharpening it requires. If a tool has a chip in the blade surface or if the blade has ground down, begin with a file. A farmer’s file has two grits of fineness, a coarse side and a medium side. For blades that are severely damaged that need an overhaul, begin with the coarsest grit on the farmer’s file. Use the file at a slight angle to the blade edge, keeping the general shape of the edge in mind as you file.

Tools are sharpened from coarsest grit to finer grit, with each level of sharpening getting a little finer. In the second level of sharpening any marks left on the tool from the previous level of sharpening are erased by the new sharpening tool. The tools in order from coarsest to finest:

- Farmer’s File (2 grit sizes)

- Steel wool

- Sharpening Puck (2 grit sizes)

- Leather Strop with honing compound (finest grit and polish)

At each level, the next finest grit is used to remove the marks of the sharpening tool before it. By the time you get to the leather strop, the blade will be highly polished, with a keen edge that will last through a day of work.

When you are sharpening a smaller blade or a blade that still has a good edge, you can just use the leather strop to improve the cutting edge. There’s no need to start at the file every time. The file is for jobs where the edge is damaged or terribly dull.

When sharpening always preserve the angle of the edge. Don’t try to drastically change an edge or you may end up creating a dangerous tool hazard that’s no longer able to do the job it was meant to do. Sharpening is the most critical job for tool maintenance.

How Grandpa fixed a rusty tool head

If a tool is left out in the weather and becomes rusty, a solution of 1 tablespoon of salt and just enough vinegar to make a thick paste, can be rubbed on the metal in a circular motion, to remove the iron oxide. This should be repeated until all the rust has been removed. Then the tool should be rinsed in clean water. Sharpening of the blade can be done while the tool is damp, but the metal should be thoroughly dried and properly lubricated with a light coating of oil, before it is put away. Use the sharpening tips above to true the blade on axes, knives, hoes, and hori hori tools before you put them away.

Grandpa rubbed metal tools with oil at the end of the season

To keep the metal rust-free in a cold, damp garage, grandpa rubbed the tool heads with an oily cloth to maintain proper lubrication. Mineral oil or machine oils can be used for this task or a beeswax compound. The oil coated the metal and protected it from humidity. Cold weather can cause water vapour to condense on the surface of metal tools, but by oiling the metal surfaces are protected from rust and discolouring in storage.

Cold weather can weaken the metal on tools so allowing them to warm up before use can help them maintain their edges better.

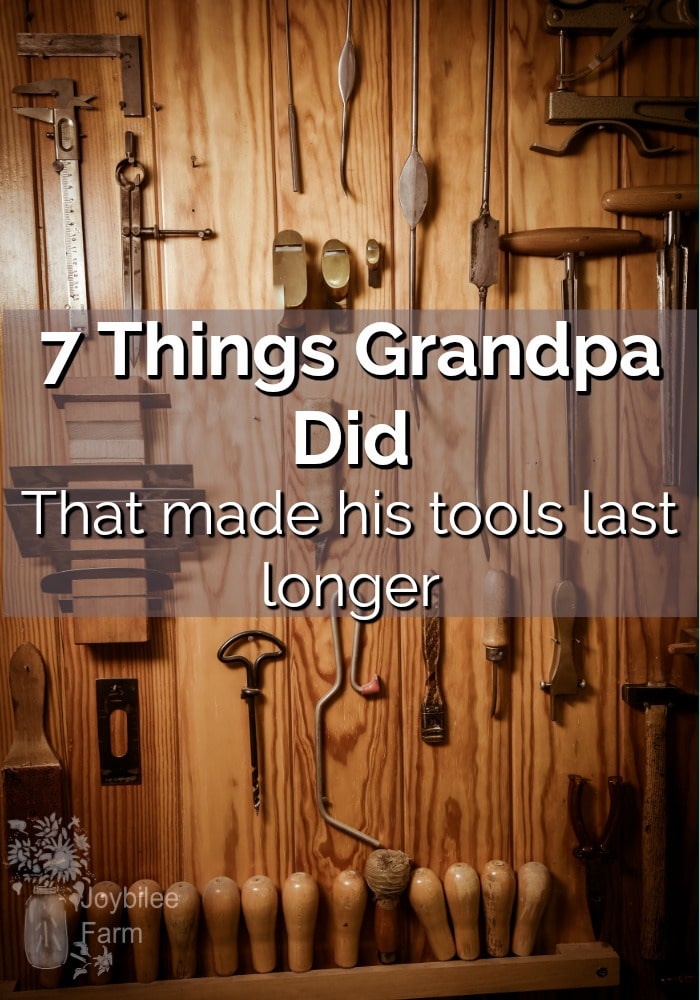

Grandpa stored tools in their proper place

Grandpa stored his tools in a shed or garage, by hanging them up off the floor, or placing them in a box reserved for tool storage. Everything in its place allowed him to take quick inventory of what he had and which tools would need replacing or maintenance before they would be needed again. Ever walk into the garage looking for a tool and end up spending hours trying to find it instead of getting the job done you needed the tool for? Grandpa learned to put tools in their proper place at the end of the work day so he didn’t have to look for a lost tool.

By hanging the tools up off the floor, tools are prevented from knocking against each other or being damaged by other tools. The tools were organized and easy to find. Rodents were kept away from gnawing at the handles or soiling the blades. The tools would be preserved for the next season of use. Grandpa would be able to find his tools when he needed them the next season.

For smaller tools like hammers, screwdrivers, fasteners, and accessories, toolboxes are essential assets. They also need their metal parts well lubricated and protected from moisture damage. If you’ve neglected yours, start now and follow these best practices to maintain their edge, their handles, and their life. With these tips you will be able to do tool repair yourself instead of calling in the professionals or replacing the tool with one of inferior quality.

Be Like Grandpa

Grab your maintenance kit and this checklist and let’s go over the 5 steps you need to do as soon as you purchase a new homestead tool or to maintain them once you have them. If you’ve got a stash of homestead and garden tools already and have never done any tool maintenance, no problem. Just start where you are at. And your grandchildren will be able to inherit your quality tools when you are done with them.

Here are the steps necessary to maintain your hand tools so that your tools can be handed down to your grandchildren:

- Start with quality tools

- Preserve wooden handles with boiled linseed oil

- Clean and preserve leather covers, belts, and bags with a leather preserver

- True and sharpen blades and tool heads

- Preserve metal tools with oil before storing them for winter

- Store the tool, properly by hanging them on the wall or storing in a toolbox.

It makes a lot of sense that when you’ve invested thousands of dollars in quality tools like the Hoss Tools Double Wheeled Hoe, a broad fork, forestry axes, splitting mauls, various hoes, rakes, and spades, to maintain those hand tools so that they last for decades and not just one season. Using these simple tool maintenance instructions many of our homestead tools have already lasted 20 to 30 years, and they still have a lot of life left.

So whether you get your tools at garage sales, estate sales, in a box, or one at a time, you need to take steps to maintain them, so that they give you years of service. Follow the steps that grandpa took with his tools to keep them sharp and in top shape and you won’t be disappointed.

Iam jelous..lol.

Those old planes are a treasure.

I’ve just inherited my Grandad’s old toolbox, I think it was his fathers before that. It’s got a set of lovely moulding planes, etc, probably last used in the ’30s, and still in great condition. Of course, I now need to learn how to use them and sharpen them etc. Naturally all the sharpening kit is there too! happy times ahead.

I have knit his sweaters, but this is one that I bought in an Irish clothing store. I fell in love with it. Knitters know amazing knitting. He wears it daily. One of his favorites. Thanks for your kind words.

Ok… I am so checking this out, however I want to say two things… 1) did you knit the sweater – it’s beautiful, and 2) your photos are great! 🙂